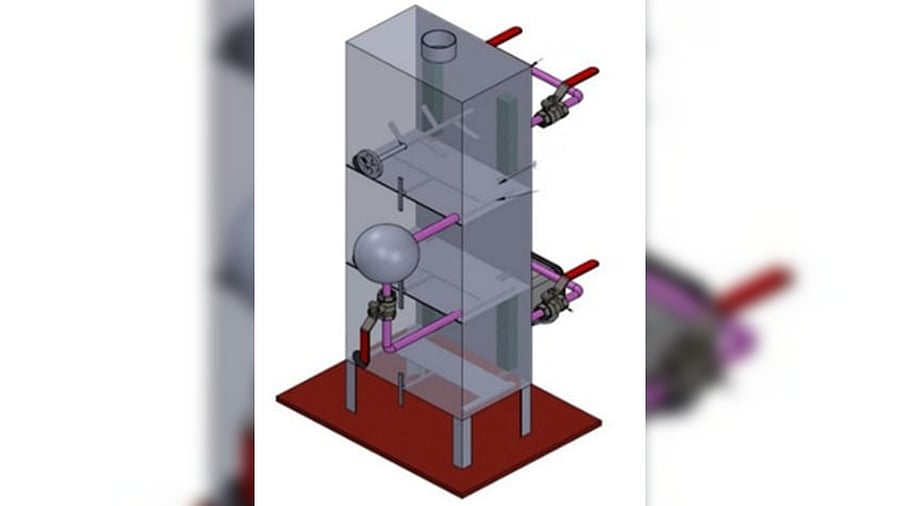

SAAnA Reactor.

Credit: DH Photos

Hyderabad: Researchers at the Hyderabad campus of BITS Pilani have created a novel solution that provides a quicker and more effective substitute for traditional waste-to-energy systems.

To tackle critical challenges in organic waste management, particularly in developing countries, the BITS Pilani team designed and patented the Sandwich Aerobic-Anaerobic-Aerobic (SAAnA) Reactor. This innovative technology significantly reduces processing time while increasing biogas yield and producing high-quality biofertilizer.

The development marks a key step towards establishing a sustainable, circular economy model for waste management. The patented reactor system is set to transform organic water processing, delivering environmental benefits and economic value through improved energy generation and fertilizer production, according to the researchers.

“Traditional waste treatment methods often fall short, requiring long processing times and generating by-products with low market value, The SAAnA Reactor is poised to change that,” said Atun Roy Choudhury, a researcher at the BITS Environmental Science and Technology (BEST) Lab, Hyderabad Campus.

Atun, along with Professor Sankar Ganesh Palani, developed the SAAnA technology to overcome the limitations of conventional waste management systems.

He informed DH that the SAAnA reactor provides a quicker and more effective way to handle a variety of organic wastes, such as fecal sludge, landfill leachate, municipal solid waste, and slaughterhouse waste.

“Unlike single-stage anaerobic digestion systems that take up to 60 days, the SAAnA reactor completes treatment in just 23 days, significantly enhancing biogas yield and biofertilizer quality,” he added.

The system runs in three precisely planned stages: 13 days of anaerobic digestion, 5 days of aerobic pre-treatment, and 5 days of aerobic post-treatment.

By managing several kinds of organic waste, either separately or in combination, in a single integrated process, the SAAnA reactor outperforms traditional systems. It significantly exceeds typical outputs, producing up to 0.8 m³ of biogas per kg of volatile solids and reducing processing time by 60% when compared to conventional anaerobic digestion systems.

“With waste disposal becoming an increasingly serious environmental issue, the SAAnA reactor presents a sustainable, scalable, and economically viable solution,” said Professor Sankar Ganesh Palani. “It reduces landfill dependence and fosters a circular economy by converting waste into valuable resources such as biogas and biofertilizers.”

Professor Palani highlighted the technology’s wide range of applications: “From municipal waste treatment plants to industrial organic waste processors, this revolutionary system has the potential to reshape the future of waste management, making cities cleaner, greener, and more sustainable.”

The researchers have filed Indian patent No. 202411062676, which has been recognized under the prestigious Kapila Scheme by the Government of India for its significant impact.